2.dr:2.3.1.2.1.3.1.dmls_sn:hg.ms.vdx.tms

Table of Contents

Fatigue strength: MS1 steel (VDx/TMS)

This page presents the S-N curves and fatigue limit of MS1 steel samples produced in the part of the production chamber near the outlet of the inert gas flow, then post-processed by heat treatment, machining that removed allowance of 0.5mm and shot-peening (in that order). The fatigue data were obtained using the bending tests of rotating bars with AM layers normal to the axis of rotation.

Production and prost-processing conditions

| Build orientation of longitudinal axis | vertical |

|---|---|

| Position with respect to inert gas flow | outlet |

| Post-processing | heat treatment → machining allowance 0.5mm → shot-peening |

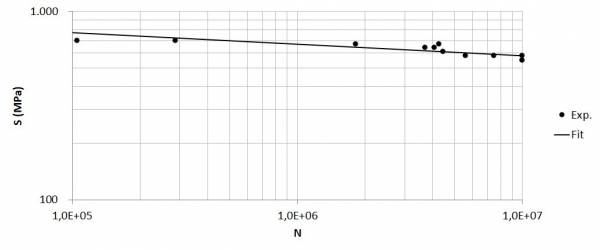

Experimental S-N curve

Wöhler curve

| Fatigue limit (MPa) | 569 |

|---|---|

| Number of cycles to failure N | N=3,63⋅10<html>51</html>⋅S<html>-16,13</html> |

| Stress amplitude S (MPa) | S=1573⋅N<html>-0,062</html> |

Explanation of the terms are given at the page Fatigue strength description.

This page is a part of the section DMLS/SLM: Fatigue design rules.

2.dr/2.3.1.2.1.3.1.dmls_sn/hg.ms.vdx.tms.txt · Last modified: 2022/01/09 17:10 by soskicz