The program of research activities will follow standard methodology for experimental research of mechanical properties, which comprises:

- definition of the desired outcomes;

- definition of initial experimental program, which consists of

- definition of samples;

- definition of loads;

- definition of measurement conditions;

- manufacturing of samples;

- characterization of samples;

- performing of initial series of tests;

- initial data analysis of the obtained experimental data;

- optional definition of additional experimental program;

- performing of additional tests;

- final data analysis;

- dissemination of the results;

- publication of the results;

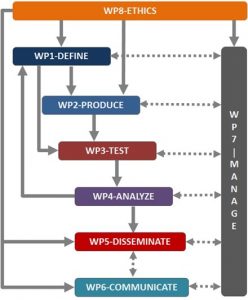

Projects activities of the same type, which lead to achievement of a common project milestone, are grouped into work packages for the sake of structured project management. The interactions between the workpackages are presented in the following figure:

The project activities that are aimed at definition of the desired outcomes, definition of initial experimental program and optional definition of additional experimental program are gathered in the work package WP1‑DEFINE.

Since the ultimate project goal is to use scientific results to support development of innovative products, the desired outcomes will be defined by mechanical designers, specialists in prototyping applications (with SP in the leading role) and specialists for tooling application (with PLA in the leading role), with methodological support of UniKv and UniBo. The desired outcomes will be defined in terms of required limiting values, functional dependencies and calculation procedures that will enable mechanical designers to predict dynamic behaviour of products manufactures by SLS. Besides, the desired outcomes will also define the final set of materials that will be used in the test campaign. This phase of the project is very sensitive, and it will have critical consequences for the remaining project activities, so it will be carefully carried out and supported by knowledge exchange between SP and UniKV, as well as between PLA and both academic partners. The aim of the secondments will be to improve academic understanding of the industrial problems, as well as to improve industrial knowledge about research methodologies. The major part in the exchanges will play experienced researchers, because the definition of the desired outcomes requires sufficient research experience and carries considerable responsibility.

Experimental program will be designed by institutions with expertise in experimental testing of materials – TOP, UniBo and UniKv. The test campaign will be planned using Analysis of Variance (ANOVA) procedures and Design of Experiment (DOE) methodologies. The development of the common experimental program will require exchange of knowledge of three important aspects of the experimental program: aspects of SLS technology relevant for mechanical behaviour of test samples, provided by UniKv, experimental testing of mechanical structures provided by UniBo, and optical measurement of deformations provided by TOP. The knowledge exchange will be also performed by exchange of experienced researchers between UniKv and TOP, as well as between UniBo and TOP.

The definition of the samples will consist of definition of its shape and definition of the manufacturing conditions. The shape of samples for impact testing and fatigue testing will be selected according to the respective ISO standards for material characterization of fatigue behaviour and impact behaviour. The shape of the samples for analysis of fracture mechanics will be based on recent research results of prof. Minak from UniBo and prof. Ćirić Kostić from UniKv. Besides, keeping in mind the future practical application of the test results, some standard product components, such as spur gears and turbine blades, will be considered as test samples. The basis for the recommendation, which will be made by the SP and PLA, will be experience in engineering of products and tools by other manufacturing technologies, with the idea to research behaviour of components that are more convenient for manufacturing by SLS than by other technologies.

The definition if test loads will be made by UniBo based on international standards, previous experiences, consultations with UniKV, who will provide their inputs on regarding the internal structure of the samples manufactured by SLS and desired outcomes as specified by SP and PLA. The definition of the measured quantities will be performed by TOP based on their expertise in measurement of deformations due to the dynamic loads.

The project activities that are aimed at manufacturing of the test samples are gathered in the work package WP2‑PRODUCE.

Test samples will be manufactured by SLS in production facilities of UniKv. The test samples will be manufactures under variable manufacturing conditions, which will be selected according to the experiences of UniKv and TOP, as well as according to the desired outcomes specified by SP and PLA. The considered variable manufacturing conditions will include orientation of the growth of the sample, powder composition and pre‑heating temperature for plastic samples and post-processing for metal samples. The spatial orientation of growth of the sample is the key parameter in these analyses, because the manufacturing process is performed layer−by−layer and the mechanical properties in the direction of growth of the object (z−direction) are generally different from the ones in the x−y plane. On the other hand, the spatial orientation of a component manufactured by SLS determines its cost (in terms of production time), and optimal selection between the costs and mechanical properties always has orientation of growth of a product as the key factor. During the phase of the manufacturing of the samples will be performed campaign of secondments of young researchers from TOP, SP and PLA at UniKv, where they will have the opportunity to be trained in advanced topics of AM and especially about the SLS technologies.

Besides the test samples manufactured by SLS in UniKv facilities, control sets of test samples will be manufactured by PolyJet technology using SP machine, and by JetPrinting using PLA machine. The main goal of introduction of control set of samples will be to separate the effects of layered structure of samples (existing in SLS set and both control sets) from the effects of microstructure specific for SLS technology. The production of two control sets aims to separate the effects of layered structure of samples from potential specific influences of PolyJet or JetPrinting printing technology.

The project activities that are aimed at characterization of samples, performing of initial series of tests and optional performing of additional series of tests are gathered in the work package WP3‑TEST.

The basis for experiments will be material testing facilities of UniBo. UniBo has the equipment and the experience in fatigue and impact testing. However, before the experimental studies of fracture mechanics, UniBo will send an experienced researcher to TOP for training in optical methods for measurement of deformations. On the other hand, young researchers from TOP, SP and PLA will be seconded during the experimental campaigns to UniBo, where they will have the opportunity to be trained on principles of experimental research and experimental mechanics. Before the experimental testing starts, a campaign of standard mechanical tests for tensile, compression and flexural strengths will be carried out on the selected objects, for the sake of proper characterization of the samples. The series of tests will also contribute to increase of the present data on static mechanical properties of objects manufactured by SLS.

The advanced mechanical properties under study in initial series of tests will be fatigue resistance, fracture toughness, crack propagation and impact resistance. The selection of the relevant advanced mechanical properties will be based on the actual components that will be selected for the study. For example, in the case of spur gears are of interest fatigue properties, for turbine blades is fundamental their impact resistance, and in the case of pressurized housings should be investigated fracture toughness and crack propagation.

For fatigue tests will be used specimens with hourglass shape defined by ISO standard, manufactured with main axis of inertia oriented along various directions with respect to the direction of sample growth. Such an approach will reveal if the fatigue properties depend on layer stacking in samples manufactured by SLS.

Regarding the fracture mechanics, the AM technologies are of special interest for studies, because the initial crack may be made (actually – manufactured!) during the production of a test sample, which is almost impossible with traditional machining systems, including electrical discharge machines. The specimens will be oriented so that the crack plane will be always parallel to the deposited layers.

The project activities that are aimed at analysis of results of initial tests and optional additional tests, as well as on definition of the design rules according to the research results, are gathered in the work package WP4‑ANALYZE.

After the initial test campaign, a team consisting of researchers from all project partners will analyse the results of the campaign. The results will certainly reveal conclusive results, but will probably show that some additional tests are needed, with a new set of samples, new set of loads, or different measurement conditions. The results may also reveal that some of the research directions are not worthy of further efforts. Based on the results of the initial analysis will be defined an additional testing campaign and the additional tests will be performed.

The results of the final analysis, which will include both results from initial and additional tests, will bring the intended results on dynamic mechanical properties of the products made by SLS. The data processing will be performed by the UniBo and UniKv, and the seconded young researchers from TOP, SP and PLA will be trained in statistical data processing by UniBo and experimental data processing procedures by UniKv.

The final phase and the crown of the complete research program is definition of the rules for design of products manufactured by SLS. In order to “translate” the results of scientific research into a useful set of rules, the researchers from academic UniKv will be seconded to SP, TOP and PLA during the project to understand the practical aspects of prototyping and tooling through participation in innovative product development in these companies. The exchange of knowledge, but also cultures, should make the intended practical results achievable. After the results of final analysis become available, a panel consisting of the experienced researchers from all project partners will define a concept of the rulebook for design of SLS products with optimal dynamic properties during a workshop dedicated solely to that purpose. University teachers from UniKv and UniBo will afterwards write the rulebook according to the concept.

The project activities that are aimed at dissemination of the rules for design of products manufactured by SLS to target groups of the project, mechanical designers and students of mechanical design, are gathered in the work package WP5‑DISSEMINATE, described in details in the chapter 2.3. The results of the effort will be disseminated through workshops, but after the project closure, the permanent dissemination of the project results will be provided via the complete rulebook of design for SLS, which will be available via public digital repository designed especially for this purpose. The research results will be also published in scientific journals and presented in scientific conferences.

Besides the activities of the research program and dissemination activities, during the whole project will be performed communication and outreach activities grouped in the work package WP6-COMMUNICATE, and management activities grouped in the work package WP7-MANAGE. Finally, the ethics issues raised by the project A_MADAM will be handled within the work package WP8-ETHICS.