Table of Contents

Process-specific design rules

The classification of the technologies used in D4AM Wiki follows the recommendations of the American Society for Testing and Materials (ASTM) group Committee F42 on Additive Manufacturing Technologies and the Subcommittee F42.05 Materials and Processes and the terminology expressed in the ISO/ASTM 52900:2015 standard, which divide all AM processes in seven families:

ISO/ASTM Definitions

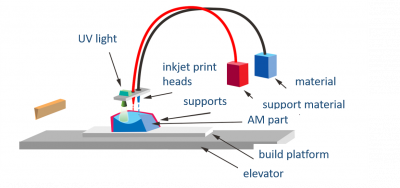

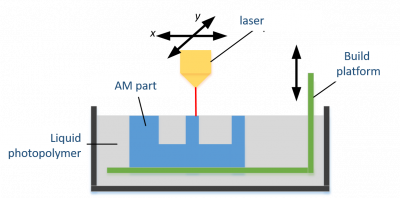

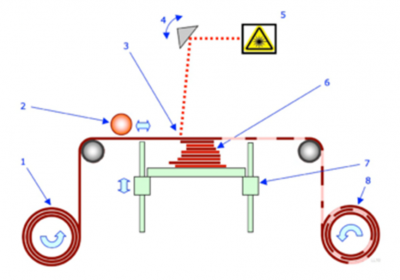

The following table presents definitions and illustrations of the basic concepts of families of AM technologies.

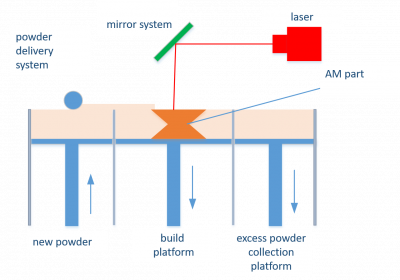

Powder bed fusion (PBF) - AM process in which thermal energy selectively fuses regions of a powder bed

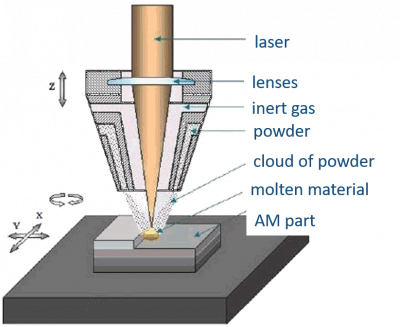

Directed energy deposition (DED) - AM process in which focused thermal energy is used to fuse materials by melting as they are being deposited

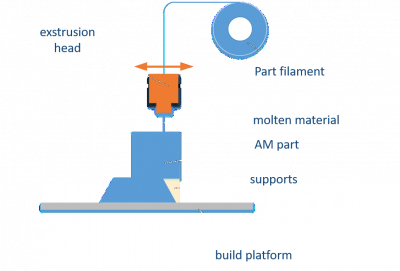

Material extrusion (ME) – AM process in which material is selectively dispensed through a nozzle or orifice

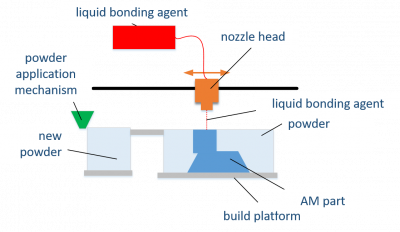

Binder jetting (BJ) – AM process in which a liquid bonding agent is selectively deposited to join powder materials

Vat photopolymerization (VATP) - AM process in which liquid photopolymer in a vat is selectively cured by light-activated polymerization

Comparison of technologies

These AM processes, apart from the common “layer-by-layer” manufacturing principle, differ in:

- types of materials and material state (powder, liquid, threads (“wire”), foils, sheets),

- method of joining of the layers,

- layer thickness and manufacturing resolution in x-y plane,

- production rate,

- maximal dimensions of products, and

- the need for technological support

which is reflected in the differences in the quality of parts, mechanical characteristics, production costs and the needs and extent of post-processing.

The following table (source: 3D Printing Handbook ) lists the materials, dimensional accuracy, advantages and disadvantages, as well as common applications of families of AM technologies, and it may serve as a brief guide for selection of the appropriate AM process depending on the desired characteristics of parts. Notification: The table is rather wide, please use the slider at the bottom of the table to move the table right and left.

| АМ process | Materials group | Common materials | Dimensional accuracy | Supports required | Strengths(+) and -Weaknesses(-) | Common applications |

|---|---|---|---|---|---|---|

| ME (FFF, FDM) | Termoplastic filament | · PLA · ABS · PEI · TPU | ±0.5% (lower limit ±0.5 mm) | Yes, dissolvable available | +Low cost +Functional parts (non commercial) -Limited dimenzional accuracy parts -Visible print layers | · Electrical housings · Form & fit testing · Jigs and fixtures · Investment casting patterns |

| VAT-P (SLA, DLP) | Photopolymer resin | · Standard · Castable · Transparent · High temperature | ±0.5% (lower limit ±0.15 mm) | Yes | +Smooth surface finish +Fine feature details -Brittle, not suitable for mechanical parts | · Injection mold-like prototypes · Jewelry (investment casting) · Dental application · Hearing aids |

| MJ | Photopolymer resin | · Standard · Castable · Transparent · High temperature | ±0.1 mm | Yes, dissolvable available | +Best surface quality +Full color and multi-material available - Brittle, not suitable for mechanical parts -Higher cost than SLA/DLP for visual purposes | · Full color pototypes · Injection mold-like prototypes · Low run injection molds · Medical models |

| BJ | Sand or metal powder | · Stainless/Bronze · Full color sand · Silica (sand casting) | ±0.2 mm (metal) ±0.3 mm (sand) | No | +Low cost +Large build volumes +Functional metal parts -Mechanical properties are not as good as DMLS/SLM | · Functional metal parts · Full color models · Sand casting |

| PBF-polymer (SLS, MJF) | Termo-plastics powder | · Polyamide (Nylon) PA-11 · Polyamide (Nylon) PA-12 · PA-12 glass bead or aluminium filled · Thermo-plastic elastomer · Polyetherketone · Carbon fiber reinforced polymers | ±0.3% (lower limit ±0.3 mm) | No | +Functional parts with good mechanical properties +Complex geometries -Longer lead times | · Functional polymer parts · Complex ducting (hollow design) · Low run part production |

| PBF-metal (DMLS/SLM, EBM) | Metal powder | · Steels · Nickel alloys · Aluminum · Titanium · Cobalt chrome · Copper | ±0.1 mm | Yes | +Strongest functional parts +Complex geometries -Small build sizes -Highest price point of all technologies | · Functional metal parts (Aerospace and automotive) · Injection molding tools with conformal cooling · Medical · Dental |